Westview Engineering has been involved in many projects that relate to the construction of facilities, tie-in of facilities to pipelines and completion of skids to complete custody transfer measurement. This work has included not only design and construction, but assistance in land acquisition and regulatory support.

Take a look at some of our projects.

Facilities

Secure Energy Mini Waste Facility

Westview Engineering Ltd. designed a portable mini waste facility to treat up to 115 m3/day of waste for Secure Energy. We completed the detailed engineering phase of the project, delivering a complete Issued For Construction (IFC) package containing: mechanical, civil, structural, and electrical drawings, and a 3D model as well.

The facility consists of five skid mounted tanks (1 fresh water tank, 1 waste tank, 1 emulsion tank, 1 process water tank, and 1 centrifuge waste tank), waste processing building, solids pad, hopper building, receiving pad, pump building, low pressure flare system, and glycol utility building. The facility also has a master control centre (MCC) building, an office, and shop trailers.

Shell Raw Water Treatment Upgrade

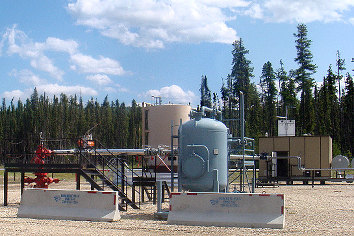

We installed a water clarifier to assist in the water treatment system of river water in Jumping Pound, Alberta. The clarifier will process 2400 m3/d of water reducing the turbidity from approximately 2000 NTU to less than 10 NTU. The construction consists of pouring a concrete pad, erecting a building and designing the piping and layout for all the equipment. Included in the system are the clarifier tank, intercoagulation tank, transfer pumps, self-cleaning filters, chlorine injection pump and tank, coagulant injection pump and tank and polymer system. A MCC with building and concrete pad was also constructed to meet the electrical requirements.

Total Installed Cost (TIC) of the system was $2.7MM. The scope of the work provided by Westview Engineering included: Initial scope, cost estimate, facility design including P&IDs, Piping Design and 3D modeling, procurement of equipment, and construction support.

Secure Energy Portable SWD Facility

Westview Engineering recently completed the design of a Stand-alone Water Disposal (SWD) facility for Secure Energy. This facility will allow Secure to test their wells for water injection before a permanent facility is proposed. The facility is capable of disposing 1632 m3/day of produced water downhole.

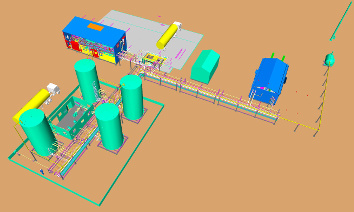

We completed the detailed engineering design, procurement, and fabrication management, delivering: scope of work, cost estimate, a complete issued for construction (IFC) package with mechanical, structural, and electrical drawings and a 3D model. The facility consists of five 500 BBL tanks (two process water tanks, two produced water tanks, and one skim oil tank), water injection skid, filtration/charge pump skid, and modular piperacks.

Pierson Oil Battery

Westview Engineering worked on the construction of a Greenfield Oil Battery in Pierson, Manitoba. The battery’s purpose is to separate the oil from the water and improve the quality of the oil such that the BS&W in the oil is less than 0.5%. The battery consists of an 8’ x 30’ FWKO, 8’ x 30’ Treater, 5 – 2000 BBL Tanks (2 – Oil Tanks, 2 – Water Tank, and 1 – Slop Tank), recycle pumps, a skim pump, two water injection pumps and two booster pumps. The battery also has an office and a MCC. The facility was designed for a rate of 5,000 bbl/d with the ability to twin the facility.

Total Installed Cost (TIC) of the facility was $5.5MM. The scope of the work provided by Westview Engineering included initial scoping, cost estimates, regulatory, facility design including P&IDs and Piping Design, procurement of equipment, and construction support.

Kakwa Multi-Stage Fracked Gas Well Tie-In

We designed this facility for 8 MMscf/d of gas, 216 bbl/d of condensate and 48 bbl/d of water. The tie-in consisted of installing a sand filter to remove proppant from the production, a 5 MMBtu line heater to prevent hydrates from forming over the chokes when taking pressure drops and a multi-phase metering package for metering gas, condensate and water. To provide flexibility, the filter and line heater were installed such that they can be easily removed and moved to the another well. A pipeline was installed to tie into the header on the main line back to the compressor station. The header needed to be expanded and future tie in points added.

Total Installed Cost (TIC) of the Tie-In was $380,000. The scope of work provided by Westview Engineering included: Initial scope, cost estimate, regulatory, facility design including P&ID’s, piping design, procurement of equipment, and construction support.

Sustaining Capital

Management Of Change Projects – Cenovus Energy

We have been completing projects for Cenovus Energy’s MOC group for the past 2 years.The primary objective is to aid in solving numerous operational issues with the end result of reducing Operational Expenditures (OpEx). Projects have included pigging reviews, water handling, material issues, equipment spacing issues, fuel usage issues, pump replacements, and metering reviews.

Total Installed Cost (TIC) for these projects have ranged from $5,000 to $150,000. The scope of work provided by Westview Engineering has included field trips, cost estimates, facility design including P&ID’s, Piping Design, procurement of equipment, and construction support.

Management Of Change Projects – Pembina Pipeline Corporation

These projects help the client increase production and efficiency at their facilities while reducing maintenance and operational costs. Projects have included operational troubleshooting, building assessment, burner management system evaluation, and cooling issues.

Total Installed Cost (TIC) for these projects has been up to $ 1.4 Million. The scope of work provided by us has included field trips to scope the project, cost estimates, facility design including P&ID’s, electrical and instrumentation drawings, piping design, procurement of equipment, and construction support.

Regulatory

Alberta D-60/ Saskatchewan S-10 Compliance

As per the Directives issued by governing bodies in Alberta and Saskatchewan, conservation economics must be completed/updated every 12 months for any sites flaring or venting combined volumes greater than 900 m3 per day and not conserving the gas. Westview Engineering Ltd. works with its clients to evaluate if their sites meet this requirement.

Scope of work completed by us includes calculating flaring and venting volumes of gas per day, fuel gas consumption rates for various pieces of equipment at the site, field trips for verifying/creating measurement schematics and completing an economic Decision Tree Analysis to determine if gas conservation is economically viable for all sites.

Pipeline Pressure Control and Overpressure Protection

Westview Engineering Ltd. has worked with more than 50 sites to ensure the proper pressure control system has been installed to meet CSA standard. According to Canadian Standards Association (CSA) Z662-11, Clause 4.18.1, a pressure control system must be installed if a pipeline may be subjected to pressure greater than its maximum operating pressure (MOP) from another source.

Westview has worked directly with TransCanada Pipeline (TCPL) to ensure that their clients were meeting TCPL’s pressure allowances.

Burner Systems B149.3 Compliance

As part of the ongoing CSA B149.3 Compliance requirement for all burner systems in the provinces of Alberta and Saskatchewan, Westview Engineering Ltd. worked closely with its clients to evaluate (and upgrade if necessary) the burner management systems currently installed at various sites.

Scope of Work completed by us for these projects included reviewing P&ID’s, inspections of older sites and obtaining quotes to perform the upgrades required. For companies based in Alberta, we have also worked with our clients for compiling a list of all the sites with burners systems installed to be submitted to the Alberta Energy Regulator (AER).

Pipeline Integrity Management

Westview Engineering Ltd. has worked with multiple clients in completing both pipeline discontinuations and abandonments. Energy Resources Conservation Board’s (ERCB) Pipeline Regulation states that a pipeline that has not been in active service in the last 12 months must be discontinued, abandoned or return to active service.

Westview is well versed in the necessary procedures to comply with ERCB’s regulation. Westview has worked closely with the Alberta Energy Regulator (AER) to work in accordance with Directive 56 and notifying the Facilities Applications.

FEED Studies

Cenovus Energy MEOR Air Injection Package

We performed a Front End Engineering Design (FEED) study for a Microbial Enhanced Oil Recovery (MEOR) air injection pilot project. The study looked into the feasibility of oxygen injection to promote microbial growth at a facility that has an anaerobic activated environment for recovery of oil (AERO) package.

The FEED study provided by Westview Engineering included: design consideration, calculations, cost estimates, regulatory, risk assessment, and risk mitigation. Design considerations included an air injection package, corrosion monitoring, explosion hazard assessment, methane removal, and noise regulations.

Grizzly Oil Sands Butane Rail Unloading

Westview Engineering conducted a FEED study of the feasibility of a butane rail unloading station. Best engineering practices were used while adhering to regulatory jurisdiction to achieve the client’s desired throughput.

The FEED study provided by Westview Engineering included: designed basis memorandum (DBM), preliminary design, cost estimate, a hazardous area study and regulatory review. The design consisted of a liquefied petroleum gas (LPG) storage bullet, vapor recovery system, transfer pumps, pipeline, and rail unloading to transfer butane from rail cars to the pipeline.

Pipelines

Pierson Gathering System

Westview Engineering Ltd. designed a gathering system and sales oil and gas pipeline for an Oil Battery in Pierson, Manitoba. This facility transports all the emulsion and casing gas from over 65 wells in the area to seven (7) test satellites as well as to the main battery facility.

From the battery, a sales oil and sales gas pipeline were also designed by Westview Engineering Ltd. The total right-of-way was over 35 km.

The scope of the work provided by Westview Engineering included initial scoping, cost estimates and tracking, regulatory, facility design including P&IDs and Piping Design and procurement of equipment.

Multi Well Battery

Westview Engineering Ltd. designed a multi well battery in Huntoon, Saskatchewan. This facility was designed with the capacity to process maximum production from seven (7) wells. The scope of work provided by Westview Engineering included: front end engineering design (FEED) study, cost estimate, facility design including a complete issued for construction (IFC) package with mechanical, and structural drawings and a 3D model.

This facility consists of group separator, test separator, header building, and pipeline gathering system. New riser systems at all seven well sites were installed, as well as underground pipeline to transport the oil effluent to the facility and into a header building which feeds into the separators.